So, what is up with all the fall/autumn/pumpkin/fest beers being out already? It's the middle of August. It is hot still. I, personally, don't really want to see those in the shelf til after Labor Day. Autumn doesn't even start until September 21. Maybe you've had similar thoughts.

I liken it to being able to buy a 2013 car now. It is like we are living in the future! But facetiousness aside, if you are releasing a pumpkin beer or a harvest ale on August 1, that means you were brewing it in June. Where do you buy pumpkin in June? Surely you aren't getting the freshest pumpkins around... Expired canned pumpkin anyone? If you are releasing a fest beer, at least there aren't any special, seasonal ingredients. But it takes longer to make. When were you brewing that one? May? April? Earlier?

I understand trying to get your product out first so people see it, remember it, and buy it. But give us a little bit of a break and at least wait until the temperatures drop out of the 90s.

I'll be holding off on the pumpkin beers for a little while. How about you? Are you excited to see all the fall beers out now or do you wish they would wait?

I liken it to being able to buy a 2013 car now. It is like we are living in the future! But facetiousness aside, if you are releasing a pumpkin beer or a harvest ale on August 1, that means you were brewing it in June. Where do you buy pumpkin in June? Surely you aren't getting the freshest pumpkins around... Expired canned pumpkin anyone? If you are releasing a fest beer, at least there aren't any special, seasonal ingredients. But it takes longer to make. When were you brewing that one? May? April? Earlier?

I understand trying to get your product out first so people see it, remember it, and buy it. But give us a little bit of a break and at least wait until the temperatures drop out of the 90s.

I'll be holding off on the pumpkin beers for a little while. How about you? Are you excited to see all the fall beers out now or do you wish they would wait?

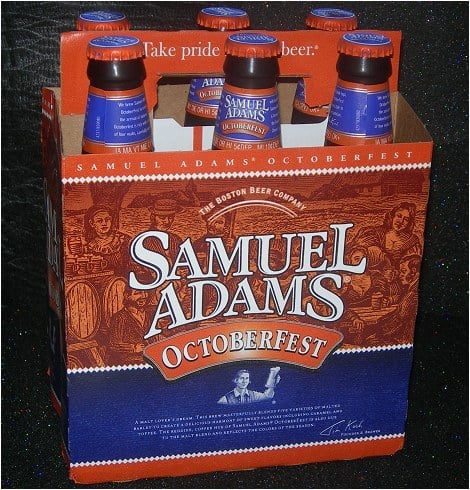

I wish they'd wait, but that still didn't stop me from buying some Sam Adams Octoberfest last week. I have no idea when they'll 'stop' selling it, so I figured I better get it now before I wait until its too late and they have the Christmas beer out in October....

ReplyDeleteI will be curious to see which comes out first: Christmas beers or Christmas decorations.

ReplyDelete